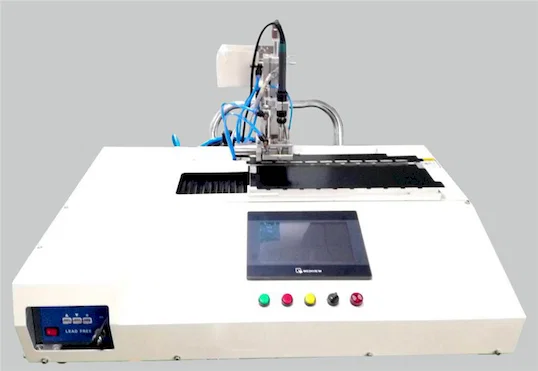

WPM-142 全自動 LED 模組焊錫機 - 在 LED 模組生產中實現卓越的品質和效率

使用WPM-142提升您的LED模組製造:自動精密焊接,實現無與倫比的品質和輸送量

介紹:

在

在當今競爭激烈的 LED 照明市場中,實現始終如一的

高品質的焊接對於產品性能和使用壽命至關重要。

介紹 WPM-142 全自動 LED 模組焊錫機,

旨在徹底改變您的 LED 模組的尖端解決方案

生產。這台先進的機器實現了整個焊接的自動化

工藝,超越了手工焊接和交付的限制

卓越的焊點,提高生產速度,並顯著

節省人工成本。體驗LED模組製造的未來

使用 WPM-142,並將品質和效率提升到一個新的水準

您的生產線。

主要特點和優勢: 自動化、品質和無與倫比的效率

這

WPM-142 LED 模組焊錫機專為卓越的設計

性能和易用性,提供一整套功能

旨在改變您的 LED 模組製造流程:

-

完全自動化,實現卓越的焊接品質和一致性:消除手動焊接中固有的可變性和不一致性。WPM-142 提供全自動焊接、

確保每個焊點始終如一的高品質並超越

可通過手動方法實現的標準。體驗戲劇性的

提高焊點可靠性和整體產品性能。

-

提高焊接品質 - 無假錫,完美的程式執行:保證完美的焊點並最大限度地減少缺陷。這台機器配備了精心設計的完美焊接程式,以消除常見的焊接問題,例如

“假錫”或冷焊點。始終如一的可靠體驗

堅固的焊接連接,減少返工並增加產品

壽命。

-

高速輸出,實現最大生產輸送量:提高產量並滿足苛刻的期限

卓越的速度和效率。WPM-142 實現了令人印象深刻的輸出

率:

-

LED 模組產量:每小時 3000~5000 件

-

燈柱產量: 每小時 2000~3000 件

這個

高速能力顯著提高您的產量

輸送量,允許您製造更多的LED模組和燈柱

在更短的時間內並優化您的運營效率。

-

顯著節省工作力成本 - 減少 4-5 名工作力: 大幅減少您的人工費用並提高您的底線。WPM-142 提供的自動化功能使每台機器可節省 4 至 5 名工人,

將寶貴的人員解放出來從事其他關鍵任務,以及

顯著降低您的總體人工成本。體驗快速

通過減少對勞動力的依賴和提高投資回報

自動化。

-

大功率加熱控制器,實現穩定的連續焊接:確保一致和可靠的焊接性能,即使在

連續的大批量生產運行。該機器具有大功率加熱控制器,保證了連續焊接的穩定性。

這種堅固的加熱系統可保持一致的溫度和熱量

交付,對於生產均勻和高品質的焊點至關重要

貫穿延長的生產週期。

-

雙焊頭提高輸送量和效率: 使用雙焊頭最大限度地提高焊接速度和效率。WPM-142 配備兩個烙鐵頭,每次可焊接 2 點。這種雙頭設計有效地將您的焊接能力提高了一倍,進一步加快了生產速度並縮短了周期時間。

-

Dual-Rail Structure for Increased Stability and Precision: Enhance machine stability and minimize vibrations for improved soldering accuracy. The WPM-142 incorporates a dual-rail structure,

providing a more stable and robust platform for the soldering process.

This enhanced stability minimizes movement and vibration, contributing

to increased soldering precision and consistent quality output.

-

Precise Temperature Control for Optimal Soldering Results: Tailor the soldering process to your specific materials and requirements with a wide range of temperature control (0-480℃).

This adjustable temperature range allows for precise optimization of

soldering parameters, ensuring optimal solder flow and joint formation

for various LED module components and solder types.

-

Accurate Tin Output Control via Stepper Motor: Minimize material waste and ensure consistent solder application with precise control of the tin output via a 420 stepper motor.

This advanced control system allows for fine-tuning of solder wire

feed, ensuring accurate and repeatable solder dispensing, reducing

material consumption, and improving the consistency of solder joints.

-

Intuitive Single-Chip Program Control System: Operate and manage the machine with ease using the user-friendly single-chip program control system.

This intuitive control interface simplifies setup, programming, and

operation, minimizing training time and maximizing operator efficiency.

-

High-Frequency Heating Soldering Heads for Rapid and Efficient Heat Transfer: Experience rapid and efficient heating for faster soldering cycles and reduced energy consumption. The soldering heads utilize 120W high-frequency heating,

providing rapid heat transfer to the soldering point. This efficient

heating method contributes to faster soldering speeds and reduces

overall energy consumption.

-

Belt Drive Transfer Method for Smooth and Reliable Material Handling: Ensure smooth and consistent movement of LED modules through the soldering process with the belt drive transfer method.

This reliable transfer system provides controlled and predictable

movement, minimizing product handling issues and contributing to

consistent soldering quality.

-

Versatile Wire Diameter Support (0.1mm-1.2mm): Adapt to various soldering requirements with a wide supported in wire diameter range of 0.1mm-1.2mm.

This versatility allows you to use different solder wire gauges based

on the specific needs of your LED module designs and soldering

applications.

-

Ultra-Fast Soldering Speed (0.01 sec): Achieve incredibly fast soldering times with a soldering speed of 0.01 seconds.

This rapid soldering capability contributes to the machine's overall

high throughput and minimizes cycle times, maximizing your production

efficiency.

-

Exceptional Repeat Accuracy (±0.02mm): Guarantee consistent and precise solder joint placement with a high repeat accuracy of ±0.02mm.

This exceptional precision ensures accurate solder deposition,

minimizing errors and maximizing the reliability of your LED module

connections.

-

Straight Line Track Slide Mode for Smooth and Predictable Movement: Ensure smooth and controlled movement of the soldering heads with the straight line track slide mode.

This linear motion system contributes to precise and predictable

soldering head positioning, further enhancing soldering accuracy and

consistency.

-

Robust Aluminum CNC Engraving Governance Structure: Built for durability and long-lasting performance. The machine's governance structure is constructed using aluminum CNC engraving,

providing a robust and rigid frame that minimizes vibrations and

ensures long-term stability and reliable operation in demanding

production environments.

Technical Specifications:

|

Voltage

|

AC220V-50Hz

|

|

Size

|

45cm50cm60cm

|

|

Weight

|

45kg

|

|

Power

|

350W

|

|

Max Stroke (Y-axis)

|

260mm

|

|

Max Stroke (Z-axis)

|

120mm

|

|

Range of Temperature

|

0-480℃

|

|

Control of Tin Output

|

420 stepper motor

|

|

Control System

|

Single-chip program

|

|

Soldering Head Tip OD Support

|

1.0-5.5mm

|

|

Soldering Head Heat Method

|

120W high-frequency heating

|

|

Transfer Method

|

Belt drive

|

|

Supported Wire Diameter

|

0.1mm-1.2mm

|

|

Soldering Fast Speed

|

0.01sec

|

|

Repeat Accuracy

|

±0.02mm

|

|

Track Slide Mode

|

Straight line

|

|

Governance Structure

|

Aluminum CNC engraving

|

Applications:

The

WPM-142 Full Automatic LED Module Soldering Machine is ideally suited

for high-volume production of various LED lighting products, including:

-

LED Modules: Automated soldering of LEDs onto PCBs for various module types.

-

LED Lamp Posts: High-speed soldering in the manufacturing of LED lamp posts and light fixtures.

-

LED Strips: Efficient soldering for high-volume LED strip light production.

-

LED Displays: Automated soldering for LED

English

English Malay

Malay Swedish

Swedish Finnish

Finnish Danish

Danish Norwegian

Norwegian Polish

Polish Greek

Greek